How to Choose an Injection Molding Machine With Robot?

When selecting an Injection Molding Machine With Robot integration, careful consideration is essential. An injection molding machine with robot features can improve production efficiency. However, the decision process isn't always straightforward. Many factors come into play.

You must assess your specific production needs. What type of products are you manufacturing? The complexity of these items affects your machine choice. Additionally, consider the robot's functionality. Does it handle loading and unloading tasks effectively? Many machines offer various degrees of automation, but not all meet every requirement.

Budget is another crucial aspect. Expensive options might promise high efficiency but could exceed your financial limits. It’s vital to balance cost and functionality. Some users find themselves overwhelmed by choices. Can they truly utilize all features? This reflection is necessary for making an informed decision. Choosing the right injection molding machine with robot integration requires thorough analysis and practical thinking.

Understanding Injection Molding: Key Concepts and Terminology

Injection molding is a complex process. Understanding its key concepts is crucial for success. The flow of plastic is one vital element. This refers to how the material moves through the mold. A good flow can ensure quality parts, while poor flow leads to defects.

Another important term is cycle time. This is the time taken for one complete production cycle. Lower cycle times are desirable, but they must not compromise quality. Often, balancing speed and precision is challenging. The machine settings must be fine-tuned.

Mold temperature also affects the process. If the temperature is too high or too low, it impacts product quality. Thermoregulators can help maintain optimal temperatures. However, not every factory uses them effectively. Sometimes, operators overlook these details, leading to inconsistencies. Ultimately, a solid understanding of these concepts enhances decision-making when selecting the right injection molding machine and automation solutions.

Evaluating Your Production Needs for Automation and Efficiency

Choosing the right injection molding machine requires a detailed evaluation of your production needs. Automation has been on the rise. According to a report by Allied Market Research, the global industrial automation market is expected to reach over $300 billion by 2027. This shift reflects industries striving for efficiency. However, many companies often overlook specific production requirements.

Understanding your production volume is crucial. High-volume productions generally benefit from more automation. However, low-volume production might not justify the initial investment. A study by the International Society of Automation shows that businesses can improve operational efficiency by up to 30% with suitable automation processes. Yet, not all production lines will see such gains. Sometimes, extensive automation can lead to higher operational costs, offsetting savings.

The choice of a robot for injection molding also depends on the type of parts produced. Simple designs may not need advanced robotics. On the other hand, complex components could require sophisticated automation. Keeping an eye on both immediate needs and future growth is vital, as market demands can shift unexpectedly. Understanding these factors ensures better decisions, but it doesn't eliminate the risks involved.

How to Choose an Injection Molding Machine With Robot? - Evaluating Your Production Needs for Automation and Efficiency

| Production Criteria | Importance (1-5) | Recommended Machine Type | Automation Level (%) | Cycle Time (seconds) |

|---|---|---|---|---|

| Production Volume | 5 | High-Output Machine | 90 | 15 |

| Product Complexity | 4 | Multi-Function Machine | 80 | 20 |

| Material Type | 3 | Standard Machine | 70 | 25 |

| Floor Space Availability | 2 | Compact Machine | 60 | 30 |

| Budget Constraints | 5 | Economical Machine | 50 | 35 |

Types of Injection Molding Machines and Their Features

When selecting an injection molding machine, it's essential to understand the different types available. Each machine type has unique features and benefits. Hydraulic machines are often chosen for their power and versatility. They excel at producing large parts, but energy costs can be high. Servo-driven machines, on the other hand, offer energy efficiency and precision. Yet, they may come with a higher upfront cost.

Electric injection molding machines are popular for small to medium-sized parts. They provide faster cycle times and lower overall maintenance. However, they may not have the power needed for larger items. Understanding these types helps in making the right choice for your production needs. Some users might overlook their production volume requirements. This could lead to choosing an unsuitable machine.

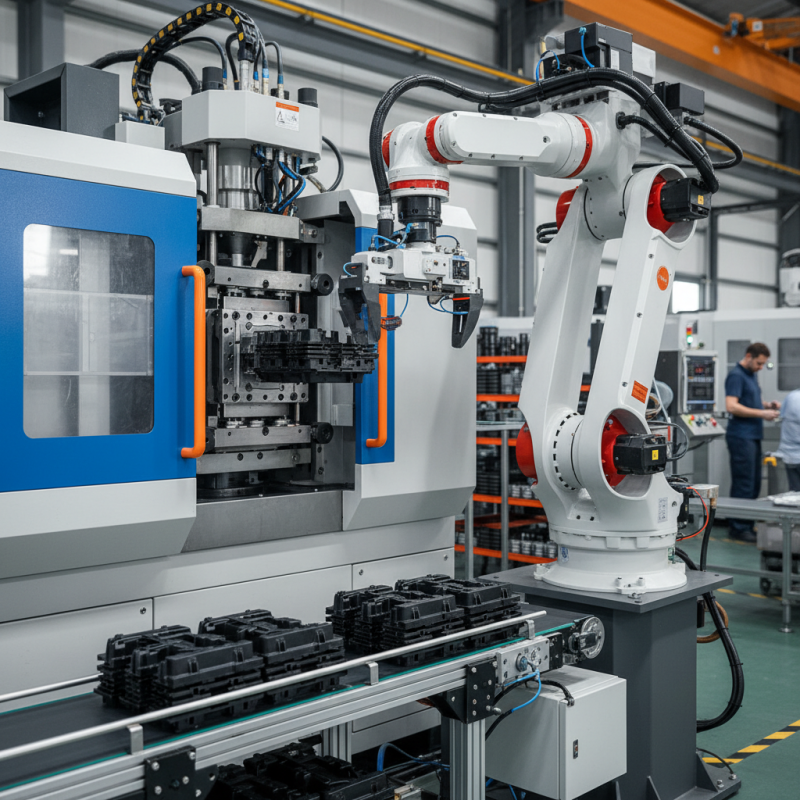

Robotics in injection molding brings automation and efficiency. Incorporating a robot can optimize production processes. For example, a robot can assist with part removal, reducing cycle times. However, the integration complexity can be daunting. Users may face challenges during setup. Reflecting on the balance of cost, efficiency, and simplicity is crucial when selecting the right machine and robot combination.

Comparison of Different Types of Injection Molding Machines

This chart illustrates the comparison of different types of injection molding machines based on their features score. Electric and Hybrid machines score the highest due to their efficiency and precision, while Micro machines are essential for small-scale productions.

Selecting the Right Robot for Your Injection Molding Machine

Choosing the right robot for your injection molding machine enhances efficiency. A suitable robot can increase productivity by up to 30%. However, the selection process may overwhelm manufacturers. Various factors come into play, such as payload capacity, cycle time, and reach.

Consider the payload of the robot. It should match your mold size and weight requirements. A mismatch may result in inefficient handling or even equipment damage. The cycle time of the robot must align with the injection molding process. A delay in part removal can lead to cycle time variations, impacting overall output. The robot's reach is also critical. It should easily access all parts of the machine in order to minimize downtime.

Tips:

1. Review your product specifications before making a decision.

2. Conduct an internal assessment of your production flow.

3. Don’t overlook the training needs for your team regarding the new robotic systems.

Choosing a robot is not just about specs. Reflection on your unique production environment is crucial. A well-fitting robot facilitates smoother operations. However, a poorly chosen robot can lead to inefficiencies. Always weigh the pros and cons carefully.

Integrating the Machine and Robot for Optimal Performance

Integrating an injection molding machine with a robotic system can significantly enhance production efficiency. According to a recent industry report, automation can boost productivity by up to 30%. Selecting the right robotic interface is crucial. Compatibility between the machine and robot should be assessed carefully, as mismatches can lead to delays or errors. Using advanced simulation software can help visualize how the systems will work together.

The layout of your production line matters as well. A well-planned setup minimizes cycle times and maximizes output. Studies indicate that poorly positioned equipment can reduce overall efficiency by nearly 20%.

Regular evaluation of the integration process is important. Identify and address any issues that arise during operation. Companies often overlook this step, leading to stagnation. Remember, an adaptable system is more resilient to changes in production demands.

Another critical aspect is staff training. Operators should understand both the machine and robot functions. This knowledge can avoid mishaps. Data suggests that inadequate training can result in a 15% increase in operational errors. Investing in ongoing education will pay off. Enhancing human-robot collaboration can drive better results. Effective integration results in smoother operations and higher quality products.