How to Optimize Pipe Rack Storage for Maximum Efficiency?

Effective Pipe Rack Storage is crucial for industrial efficiency. According to a recent market report from Research and Markets, optimizing storage can reduce retrieval times by up to 30%. This efficiency gains can translate into significant cost savings and improved workflow in manufacturing environments.

The configuration of pipe racks greatly impacts space utilization and safety. Inadequate storage can lead to accidents and operational delays. Industry standards suggest that each section of a pipe rack should accommodate a specific size and weight limit to ensure stability. Observing these guidelines can minimize risks associated with poor storage practices.

However, many facilities still struggle with organization and space management. Regular audits can uncover underlying issues in inventory practices. Implementing a systematic approach to Pipe Rack Storage not only enhances safety but can also maximize operational productivity over time. Understanding these elements is essential for sustainable growth in the industry.

Understanding the Importance of Pipe Rack Storage Optimization

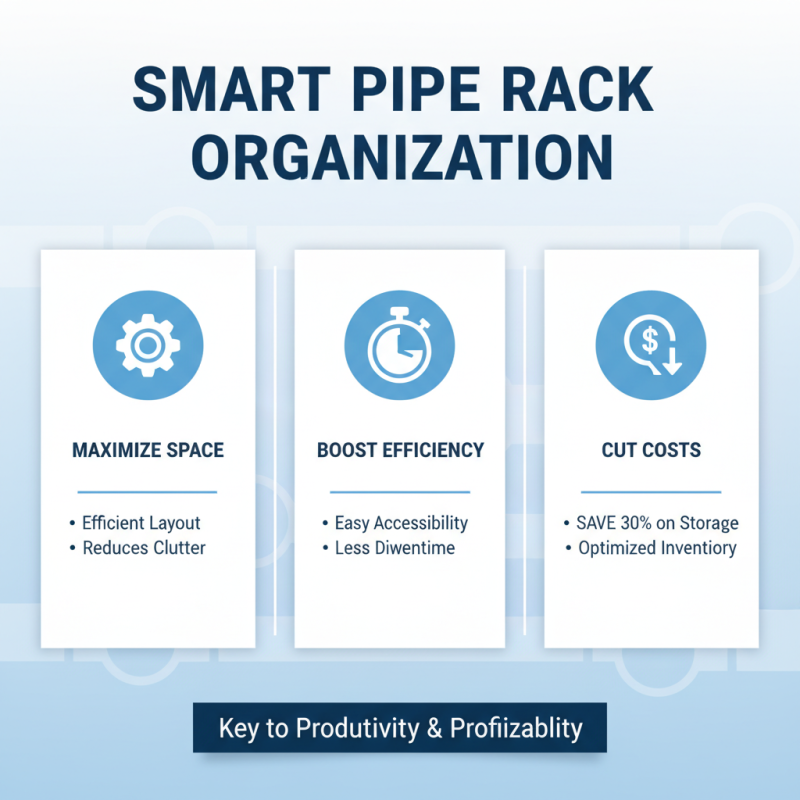

Efficient pipe rack storage is crucial for any facility handling large quantities of pipes. The way you organize and store these materials impacts overall productivity. According to industry studies, poorly designed storage systems can reduce efficiency by up to 30%. This highlights the critical need for optimization.

Effective utilization of space is essential. Arrange pipes by size and material. This reduces time spent searching for specific items. Implementing vertical storage can also save space. Studies show that vertical solutions can increase storage capacity by 50%. Consider using adjustable racking systems for flexibility, allowing for changes in inventory.

Tips: Regular audits of storage systems are vital. Identify underutilized areas. Shade may affect material integrity, so ensure proper location. Clear access routes minimize delays during material handling. Provide staff training to enhance awareness on best practices in storage optimization. Remember, even small improvements can significantly impact overall productivity.

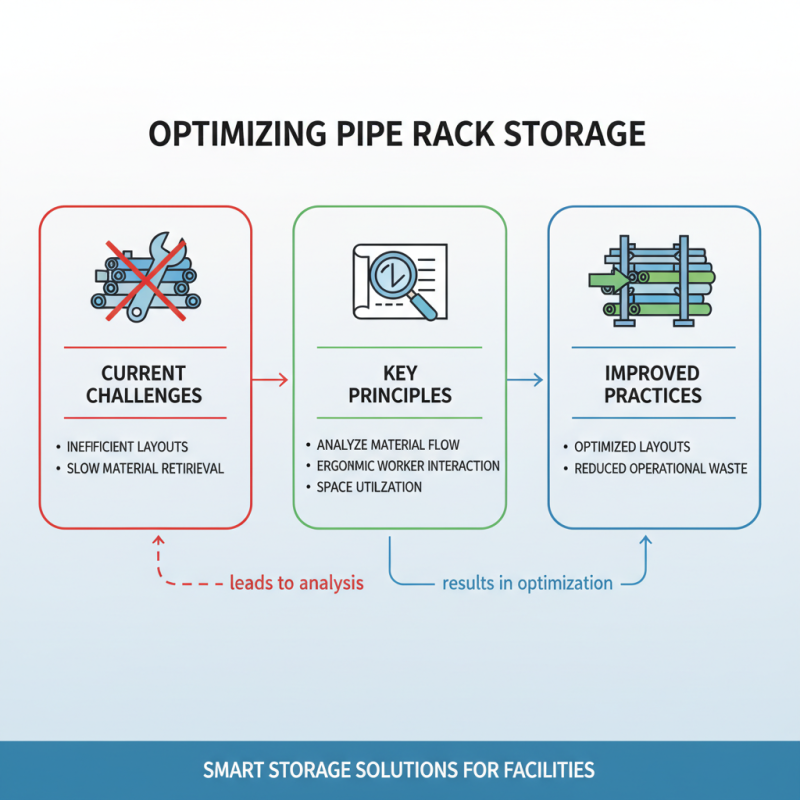

Assessing Current Pipe Rack Storage Practices and Layouts

Assessing current pipe rack storage practices requires a keen eye for detail. Many facilities overlook the importance of layout optimization. Misplaced pipes lead to wasted time during retrieval. It’s crucial to analyze the flow of materials and how workers interact with the racks.

One common issue is inadequate labeling. Workers spend precious minutes searching for the right size or type. Consider how often routine checks disrupt workflow. Clear, easy-to-read labels can alleviate this problem. An organized approach not only speeds up retrieval but also enhances safety.

Another aspect to reflect on is vertical space usage. Often, pipes are cluttered on lower shelves. Adopting a vertical arrangement maximizes available space. However, proper training is essential to ensure safe stacking. Mid-height racks can sometimes be overlooked and pose a risk if not addressed. Regular audits could reveal underutilized areas or hazards.

Identifying Key Factors for Efficient Pipe Rack Organization

Efficient pipe rack organization is crucial for maximizing storage space. Proper layout can improve accessibility and reduce downtime. According to industry studies, nearly 30% of storage costs stem from poor organization. It’s essential to identify factors that optimize pipe rack storage.

One key factor is analyzing the frequency of pipe usage. High-demand pipes should be easily accessible. This can reduce time spent searching for materials. Implementing a color-coding system can also help. It allows for quick identification of different sizes and types.

Tip: Utilize vertical space effectively. Adjustable shelving can accommodate various pipe lengths. Regular audits of your inventory can highlight underutilized areas.

Another factor is maintaining clear labeling. Labeling every section minimizes confusion. Staff members can locate pipes quickly, which enhances productivity. In a busy environment, mistakes occur. Regular training can reduce errors and improve organization.

Tip: Encourage feedback from team members. They often have insights on improving the system. Their contributions can lead to a more efficient layout. Reflect on strategies regularly. What works today may not work tomorrow.

Implementing Technology and Tools for Enhanced Storage Management

Optimizing pipe rack storage can lead to significant improvements in efficiency. One key aspect is the integration of technology. Using inventory management software helps track stock levels accurately. Barcode systems or RFID tags can streamline this process. Workers scan items upon entry and exit. This reduces the chances of errors and improves accountability.

Incorporating automated systems for storage can also offer substantial benefits. These tools can control the storage environment. For instance, temperature control can prevent material degradation. However, the initial investment in such technology may be heavy. Companies need to weigh the costs against potential long-term savings. Regular assessments of the chosen technologies are crucial. Sometimes, what works well initially may not suit changing operational needs.

Enhanced visualization tools can support better layout planning. 3D modeling systems help visualize how racks are arranged. This can lead to more effective use of space. Yet, the complexity of these tools can be overwhelming. Staff may need extensive training, which can temporarily hinder productivity. Balancing cutting-edge tools with user-friendliness is a constant challenge.

Establishing Best Practices for Maintenance and Safety in Pipe Racks

Maintaining pipe racks involves more than just organization. Regular inspections are crucial to identify wear and tear early. Signs of corrosion or damage can lead to safety risks. Workers must be trained to spot these issues.

Safety guidelines should be clear and accessible. Posting visual reminders can help reinforce proper procedures. Ensure that racks are not overloaded. Overloading can cause structural failures. Each type of pipe should have designated storage spaces.

Another consideration is cleanliness. A cluttered area increases the risk of accidents. Regular cleaning schedules can help maintain order. Workers should understand the importance of a tidy workspace. Finally, evaluate the current system regularly. Are there inefficiencies in the layout? Scheduling periodic reviews can foster a culture of continuous improvement.

Related Posts

-

2025's Top 10 Pallet Racking Systems: Optimize Your Warehouse Efficiency

-

Top 10 Commercial Racking Manufacturers from China at the 137th Canton Fair

-

Top 10 Industrial Racking Manufacturers from China at the 137th Canton Fair

-

Common Issues Faced During Pallet Racking Installation and How to Overcome Them

-

Ultimate Guide to Choosing the Best Commercial Racking Systems for Your Business

-

7 Essential Factors to Consider When Choosing the Best Tire Racks